SCREW CONVEYOR

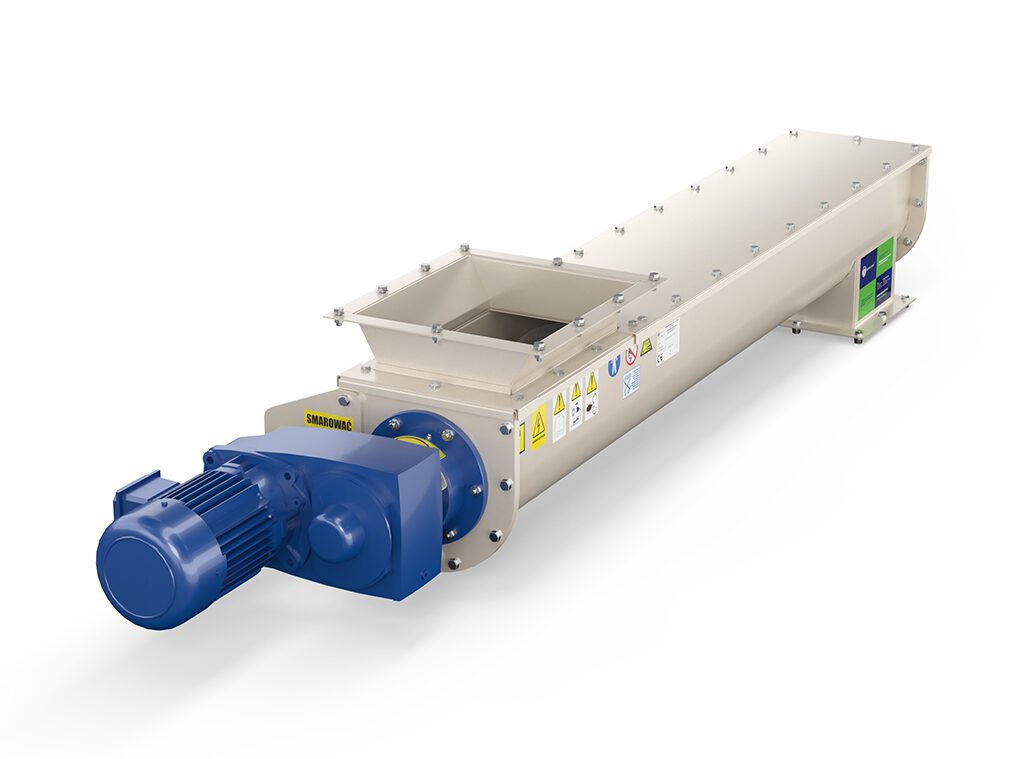

A screw conveyor is a mechanical conveying system used to move bulk materials horizontally or at a slight incline. It consists of a rotating helical screw blade, also known as an auger, contained within a tube or trough. As the screw rotates, it moves the material along the length of the conveyor, pushing it forward.

Screw conveyors find applications in numerous industries, such as agriculture, food processing, mining, chemical manufacturing, and wastewater treatment. Typical uses include conveying bulk materials from storage bins or hoppers to processing equipment, loading and unloading trucks or railcars, and transferring materials between different stages of a production process.

Screw conveyors are widely used in various industries for handling a wide range of bulk materials, including powders, granules, flakes, and even semi-solid materials. They offer several advantages for material handling:

Versatility: Screw conveyors can handle a wide variety of materials, including both free-flowing and non-free-flowing substances. They are adaptable to different material characteristics, such as particle size, moisture content, and abrasiveness.

Simple and Compact Design: Screw conveyors have a relatively simple design, consisting of a single moving part, the screw. This simplicity makes them easy to operate and maintain. They also have a compact footprint, making them suitable for installations with limited space.

Efficient Material Transfer: The screw’s helical shape creates a continuous, smooth surface that enables efficient and uniform material transfer. The rotational motion of the screw pushes the material along the conveyor without excessive shearing or degradation.

Customizable Configurations: Screw conveyors can be customized to suit specific application requirements. They can be designed in various lengths, diameters, and inclinations to accommodate the desired material flow rate, distance, and space constraints.

Cost-effective Solution: Screw conveyors are generally cost-effective compared to other types of mechanical conveying systems. They have low power requirements and offer reliable operation with minimal maintenance.

Screw conveyors find applications in numerous industries, such as agriculture, food processing, mining, chemical manufacturing, and wastewater treatment. Typical uses include conveying bulk materials from storage bins or hoppers to processing equipment, loading and unloading trucks or railcars, and transferring materials between different stages of a production process.

When considering a screw conveyor for a specific application, factors such as material characteristics, capacity requirements, distance, incline, and environmental conditions should be taken into account. It is advisable to consult with experienced engineers or conveyor manufacturers to ensure proper design and selection of a screw conveyor that meets your specific needs.

KEY BENIFITS

- Transport a wide variety of materials, including abrasive and sticky materials

- Transport materials over long distances.

- Energy-efficient.

- Easy to install and maintain.