DOME VALVE

A dome valve, also known as a double-acting dome valve or a pressure seal valve, is a type of mechanical valve commonly used in industries where the handling of abrasive or high-pressure materials is required. Dome valves are specifically designed to provide reliable shut-off and control of bulk solids, powders, and abrasive materials in pneumatic conveying systems.

Benefits of dome valves include:

Reliable Sealing: The dome valve’s unique design and sealing mechanism provide reliable shut-off and prevent material leakage, even in high-pressure and abrasive environments.

Reduced Maintenance: Dome valves are designed to resist wear and minimize material build-up, resulting in reduced maintenance requirements and extended service life.

Smooth Material Flow: The spherical shape of the dome allows for smooth material flow, minimizing the risk of blockages or clogging.

Precise Control: Dome valves offer precise control over material flow rates, making them suitable for applications that require accurate dosing or batching.

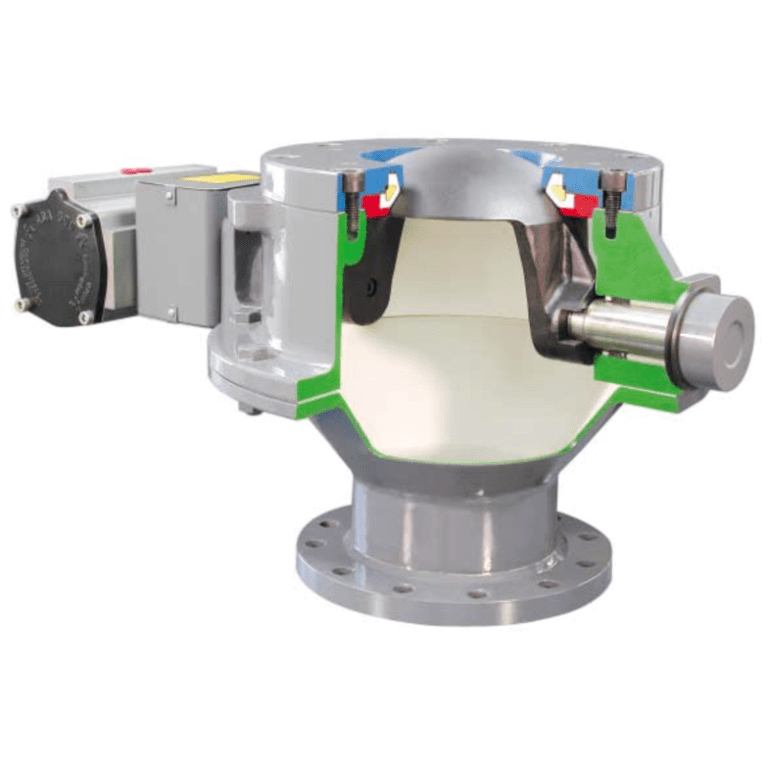

The unique design of a dome valve consists of a spherical-shaped dome or vessel that acts as a pressure vessel or seal. Here are some key features and characteristics of dome valves:

Construction: Dome valves typically have a robust construction, with a spherical or hemispherical dome that serves as the primary sealing component. The dome is made of durable materials such as stainless steel, cast iron, or abrasion-resistant alloys to withstand harsh operating conditions.

Sealing Mechanism: The dome valve utilizes air pressure to create a positive seal. When the valve is closed, the dome is pressed against a seating ring or surface, forming a tight seal to prevent leakage of materials. The dome’s spherical shape allows for even distribution of pressure across the sealing area, ensuring effective sealing.

Operation: Dome valves are double-acting valves, which means they can be opened or closed by applying air pressure to both sides of the dome. When the valve is pressurized from below the dome, it opens, allowing material to flow through. Conversely, when the pressure is applied above the dome, it closes, sealing off the flow path.

Abrasion Resistance: Dome valves are commonly used in applications where abrasive materials are handled. The spherical shape of the dome minimizes wear and prevents material build-up, making it suitable for abrasive and erosive materials.

Flow Control: Dome valves offer excellent flow control capabilities. By adjusting the air pressure applied to the dome, the valve’s opening and closing speed can be controlled, allowing for precise regulation of material flow.

Application: Dome valves are widely used in industries such as cement, mining, power generation, chemical processing, and food processing. They are particularly suitable for applications involving dense-phase pneumatic conveying systems, where reliable sealing and handling of abrasive materials are crucial.

KEY BENIFITS

- Loose flow without obstruction through the entire section

- Simple and reliable design

- Absolutely tight when closed

- Works with both static and dynamic substances.

- Pressure up to 30 bar

- High reliability and service life

- Leak proof