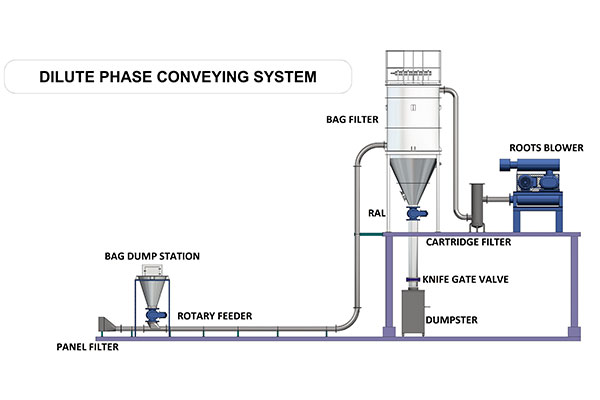

DILUTE PHASE PNEUMATIC CONVEYING SYSTEMS

Dilute phase pneumatic conveying systems are another type of material handling system used to transport bulk materials through a pipeline using compressed air or gas. Unlike dense phase systems, dilute phase systems operate at higher air velocities, which suspend the material in a carrier air stream and transport it through the pipeline in a continuous flow.

In a dilute phase pneumatic conveying system, the material is introduced into an airstream at the feed point. The high-velocity air stream carries the material particles along the pipeline, conveying them to the desired destination. The material particles remain relatively dispersed in the air stream, resulting in a lower material-to-air ratio compared to dense phase systems.

Here are some of the key features of dense phase pneumatic conveying systems:

Higher conveying velocities: Dilute phase systems typically operate at higher air velocities, which require more energy to maintain the flow and suspend the material particles.

Greater conveying distances: Dilute phase systems are suitable for longer conveying distances as the continuous flow of material allows for efficient transport over extended pipeline lengths.

Higher throughput rates: Due to the continuous flow of material, dilute phase systems are capable of handling higher volumes of material per unit of time compared to dense phase systems.

Potential material degradation: The higher air velocities in dilute phase systems can cause more abrasion and degradation of the conveyed material, especially for fragile or sensitive materials.

Increased power requirements: Dilute phase systems generally require higher power consumption due to the need for compressed air or gas at higher velocities.

The choice between dense phase and dilute phase pneumatic conveying systems depends on various factors such as the properties of the material being conveyed, conveying distance, desired throughput rates, and the level of material degradation acceptable for the application. Each system has its advantages and considerations, and the selection should be based on the specific requirements and characteristics of the material handling process.